Key Factors

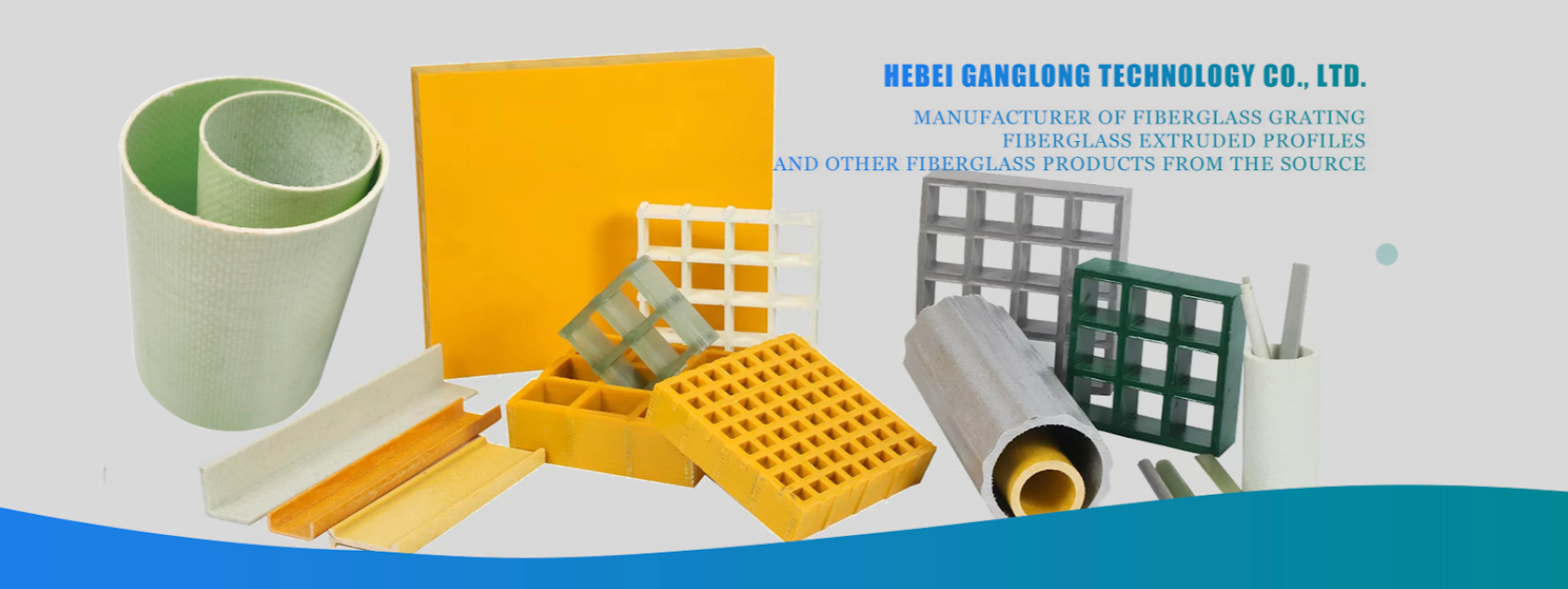

The cost of a cable ladder can vary significantly depending on several factors, including the material, size, design, load capacity, and the specific requirements of the installation. Understanding these cost factors is important for making an informed decision about which cable ladder to choose, ensuring that it fits both your budget and operational needs. GangLong Fiberglass offers a range of high-quality fiberglass cable ladders, providing durable and cost-effective solutions that meet various industrial needs. Below, we break down the main factors that influence the cost of cable ladders.

Material Type

The material used in the construction of the cable ladder is one of the primary factors affecting its cost. Common materials include steel, aluminum, plastic, and composite materials like Chopped Strand Mat (CSM) and fiberglass, with each having distinct advantages and price points:

- Steel Cable Ladders: Steel is a heavy-duty material known for its strength and durability, but it is also one of the more expensive options. Steel ladders are ideal for industrial environments where cables must bear heavy loads or endure harsh conditions. They are typically galvanized or powder-coated to prevent rust, which can add to their cost.

- Aluminum Cable Ladders: Aluminum ladders are lighter than steel and resistant to corrosion, making them a popular choice for applications where weight and rust resistance are priorities. Aluminum tends to be more expensive than plastic but less costly than steel, especially when considering its long-term durability and maintenance-free qualities.

- Plastic Cable Ladders: Plastic ladders are the most budget-friendly option and are commonly used in light-duty applications, such as for office or residential setups. They are less durable than steel or aluminum but still provide adequate cable management in environments where cables are lighter and not subject to extreme conditions.

Size and Length

The size and length of the cable ladder directly impact its cost. Longer or wider ladders typically require more material, making them more expensive. It’s important to choose the right size based on the volume of cables you need to manage, as purchasing an oversized ladder can result in unnecessary costs. On the other hand, selecting a ladder that is too small may not provide sufficient support and could lead to additional expenses for replacements or upgrades in the future. For example, when using Fiberglass Sheets in your ladder construction, the material’s lightweight nature can help reduce overall costs, but the size must be carefully matched to the load requirements to maintain structural integrity.

- Standard Lengths: Many cable ladders come in standard lengths, typically ranging from 3 meters to 6 meters. For longer installations, you may need to buy additional lengths, which can add to the overall cost.

- Custom Sizes: If you require a custom length or width for a specific project, the cost will be higher. Custom-designed ladders are generally more expensive than off-the-shelf models due to the added fabrication and specialized materials.

Load Capacity

Cable ladders are designed to handle different load capacities, and choosing a ladder that matches the weight of the cables you plan to route will influence the cost. Heavy-duty ladders that are capable of supporting larger or heavier cables are generally more expensive due to the additional reinforcement and thicker materials required.

- Light-Duty Ladders: Suitable for light cables, these ladders are typically less expensive and can handle smaller loads.

- Heavy-Duty Ladders: These are designed for larger cables or high-density cable installations and come with a higher price tag due to their robust construction and support capabilities.

Design Features

Cable ladders may come with additional design features such as bendable sections, special coatings for corrosion resistance, or adjustable brackets. These added features can increase the overall cost but may be necessary depending on the environment or specific installation requirements.

- Coatings and Finishes: For outdoor installations or areas prone to moisture, galvanized or powder-coated steel ladders are often chosen. These coatings add extra protection against corrosion and weathering but increase the cost of the ladder.

- Additional Accessories: Some cable ladders come with optional accessories such as cable tray dividers, mounting brackets, or covers to protect the cables. These accessories can add to the overall cost but may be necessary for specific applications.

Read also: Understanding Singapore’s Electrical Wiring Rules for Your Home