Door handles are basic furniture accents in daily life, particularly in homes and businesses where they are used often. Zinc metal door handles have been rather popular among consumers recently because of their durability and pleasing look. What then is the lifetime of zinc alloy door handles? The issue will be investigated in this paper from several angles.

Basic Characteristics of Zinc Alloy

Made mostly from zinc mixed with other elements including aluminum, copper, and magnesium, zinc alloys are One significant feature of zinc alloys is their:

High mechanical strength of zinc alloys enables them to resist great outside forces without deforming or breaking.

Excellent corrosion resistance of zinc alloys increases their service life and reduces their likelihood of rust in humid surroundings.

Zinc alloy’s simplicity of casting and processing makes it possible to create detailed features and complicated form door knobs.

Zinc alloy door knobs enhance their visual attractiveness by means of electroplating and painting, therefore smoothing their surface.

Manufacturing Process of Zinc Alloy Door Handles

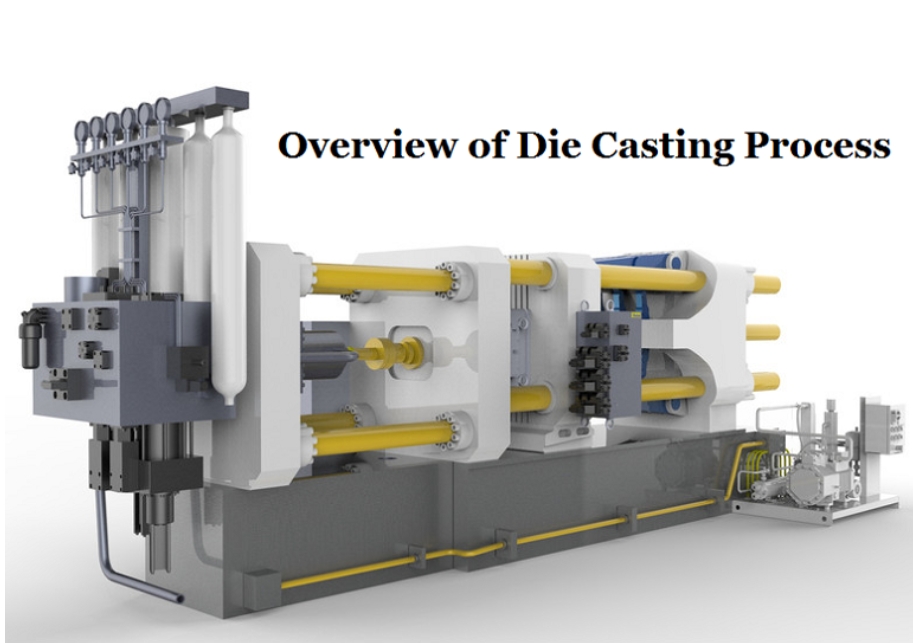

The manufacturing technique of zinc alloy door knobs influences its endurance in addition to the qualities of the material. Zinc alloy door knobs are produced mostly using these techniques:

One of the most often used manufacturing techniques is die casting. High pressure injection of molten zinc alloy into a mold rapidly cools to form. The surface is smooth and this technique may create precisely sized and intricate shaped door handles.

Polishing the produced door handle helps to remove surface burrs and unevenness, therefore enhancing its gloss.

To improve the corrosion resistance and visual appeal of the door handle, a layer of metal, say nickel or chromium, is plated onto its surface.

By means of spraying, a protective paint layer is put to the surface of the door handle, therefore enhancing its durability.

Practical Applications of Zinc Alloy Door Handles

Homes and businesses both utilize zinc alloy door knobs extensively, and their longevity has been demonstrated in actual application.

Because of their pleasing appearance and good tactile feel, zinc alloy door handles are often used for cabinet doors and interior doors. Zinc metal door knobs can keep their integrity and gloss over a long period even with regular use.

Excellent endurance of zinc alloy door knobs shows in high traffic areas like hotels and workplaces. Their resistance to wear and corrosion helps them to keep good performance even in heavy-intensity use.

Variations in surroundings might influence the lifetime of zinc alloy door handles. Especially significant in humid and dusty surroundings are zinc alloy door handle corrosion resistance and simplicity of cleaning.

Testing and Comparison of Zinc Alloy Door Handles

We may compare zinc alloy door handles with those produced of other materials, such stainless steel and aluminum alloy, so helping us to better grasp their durability.

Zinc alloy door knobs can be exposed to wear resistance and specific data on their corrosion resistance in a laboratory environment by means of salt spray testing. Zinc metal door knobs show remarkably great corrosion resistance when compared to other materials.

Generally speaking, zinc alloy door knobs keep good appearance and operation even after prolonged use from user comments. Their service life is rather long.

Maintenance and Care of Zinc Alloy Door Handles

Though zinc alloy door handles are reasonably durable, their service life can be further extended with appropriate maintenance and care.

To get stains and dust off the door handle, wipe its surface with a moist cloth daily. Strong acidic or alkaline cleaners should not be used to damage the electroplated surface.

Apply anti-rust oil often to the door handle in humid surroundings to improve its corrosion resistance.

Steer clear of sharp object-based surface scratching of the door handle. To lower too much wear, carefully use the door handle.

Conclusion

All things considered, zinc alloy door handles hold a significant place in the market because of their great strength, corrosion resistance, good machinability, and visual attractiveness. User comments and laboratory studies show that zinc alloy door handles are quite durable and lengthy. For consumers, selecting zinc alloy door handles can improve the general texture of homes and businesses and offer dependable, long-use.

Honjenny, established in 1996, is a global manufacturer of precision metal components. Specializing in zinc alloy and aluminum alloy die casting technology, Honjenny provides robust solutions for various industries, including home hardware, perfume caps, and consumer electronics. If you are looking for a manufacturer of zinc alloy and aluminum alloy die-cast products, consider contacting Honjenny.

FAQs

Are rusting prone door knobs made of zinc alloys?

Particularly after electroplating, which strengthens their rust prevention, zinc alloy door handles have strong corrosion resistance and are not readily rusted.

Are door handles from zinc alloys more costly than those produced from other materials?

Zinc alloy door handles are really reasonably priced. Though they might be more expensive than plastic or aluminum alloy door handles, they are rather less expensive than stainless steel door handles. Still, their visual appeal and robustness help them to be reasonably priced.

How can I find out if zinc alloy door knobs are of quality?

Surface smoothness, weight, and workmanship of zinc alloy door knobs let one evaluate their quality. Excellent zinc alloy door handles have a smooth surface free of burrs, reasonable weight, and superb workmanship.

By means of the aforementioned study, we can better appreciate the endurance and superiority of zinc alloy door knobs, enabling consumers to make more wise decisions.